Finishing with films

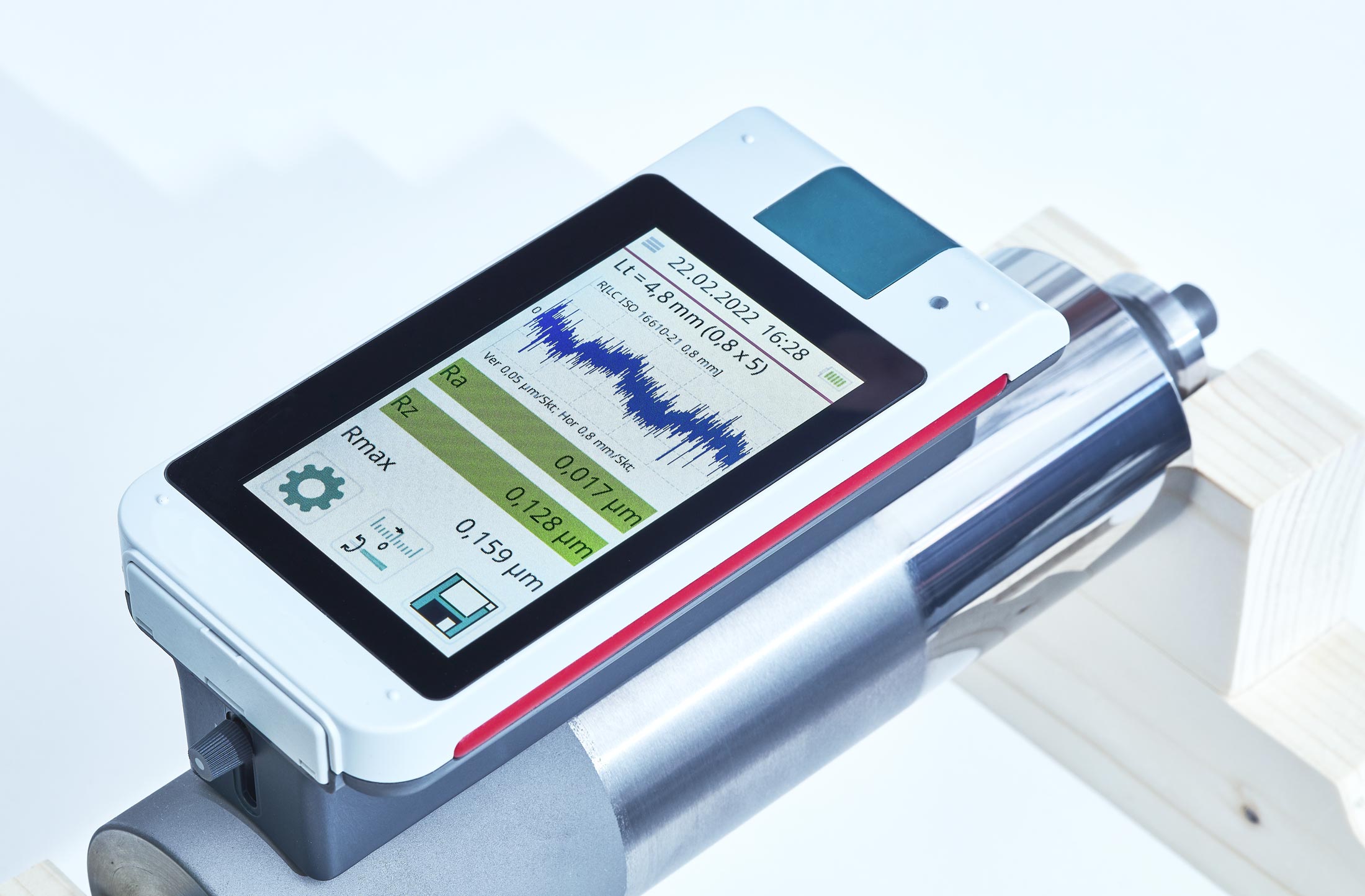

Finishing – How to use: Compared to stone finishing, finishing with films enables a consistent and constant surface right from the start. Through a controlled, continuous feed of the film, new abrasive grit is always being used. In connection with the correct feed rate, rotational speed of the work piece and the correct contact pressure an absolute precise and repeatable surface result will be achieved.

The requirements for waste removal and processing treatment of the cooling lubricants is much lower in cost, cleaner and more environmental friendly by finishing (compared to stone finishing), as ordinary lubricants can be used.

Achieving finest surfaces with process reliability

Finishing is becoming more and more important within the industrial manufacturing process as the demands on this technology are constantly increasing and the required surface results must be achieved reliably within a short time. Despite sophisticated tool technologies for grinding and complex manufacturing processes for turning, this is insufficient for an increasing number of products. Finishing is therefore the innovative further development of conventional processing methods such as grinding and polishing.

Therefore 1A-products

-

reducing the Ra-value by 50% with each machine step (empirical formula)

-

absolute repeatable surfaces and defined surface structures

-

lower wear of the work piece surfaces

-

short processing times of the work pieces

-

low friction coefficient are reducing the noise level of the parts in later use

-

environmentally sound, as ordinary lubricants and even water can be used

-

no grit attack (no scratches or commas)

-

thermally neutral working process

-

improvement of the working behavior (surface stressed parts)

-

avoidance of softening, free of surface tensions and micro cracking

Application fields

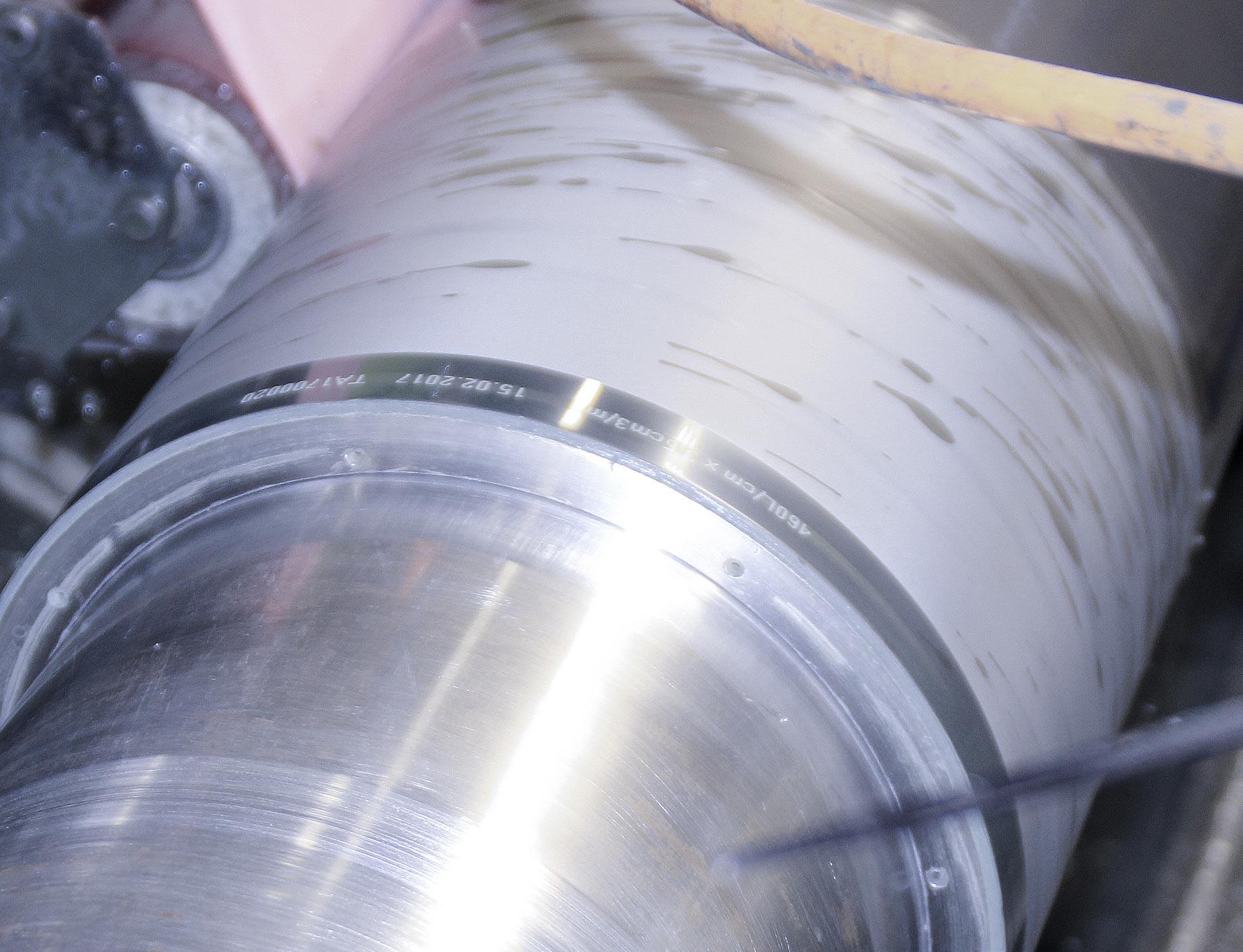

grinded roller

Superfinishing

final result

2 materials: coated – grinded – superfinished

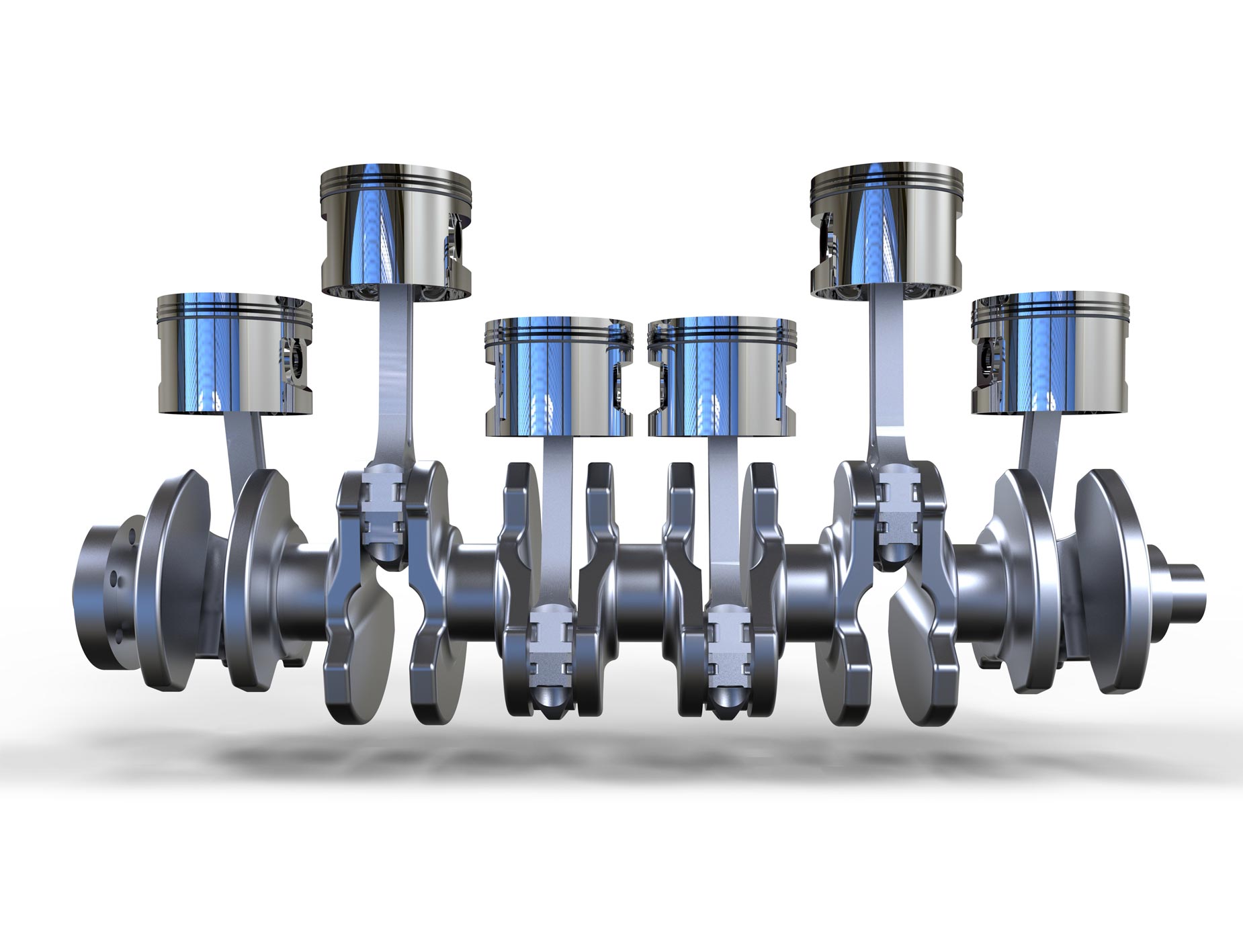

finishing of crankshafts

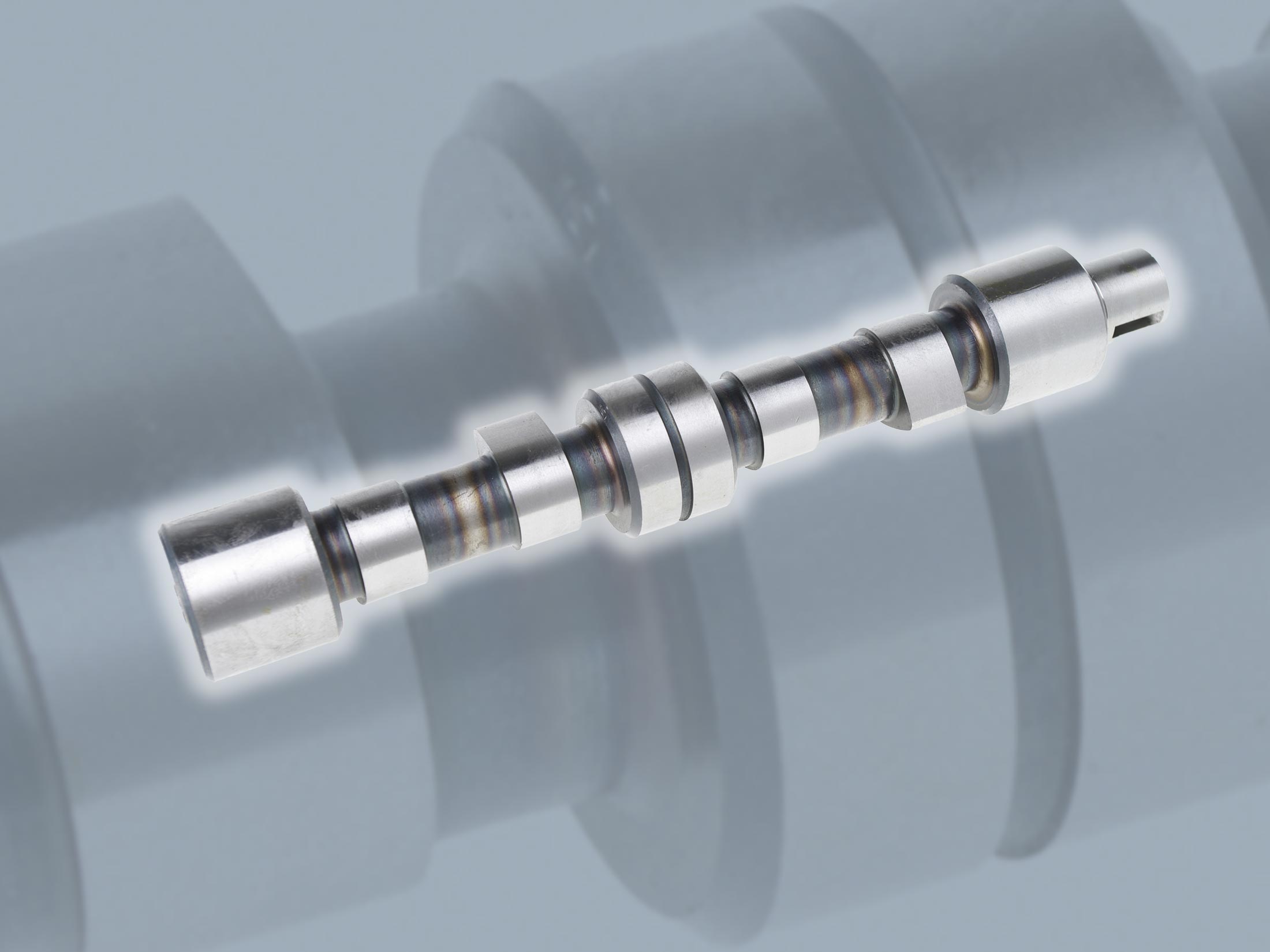

finishing of camshafts during the application process

polishing of copper rollers

polishing of connectors

processing glass edges